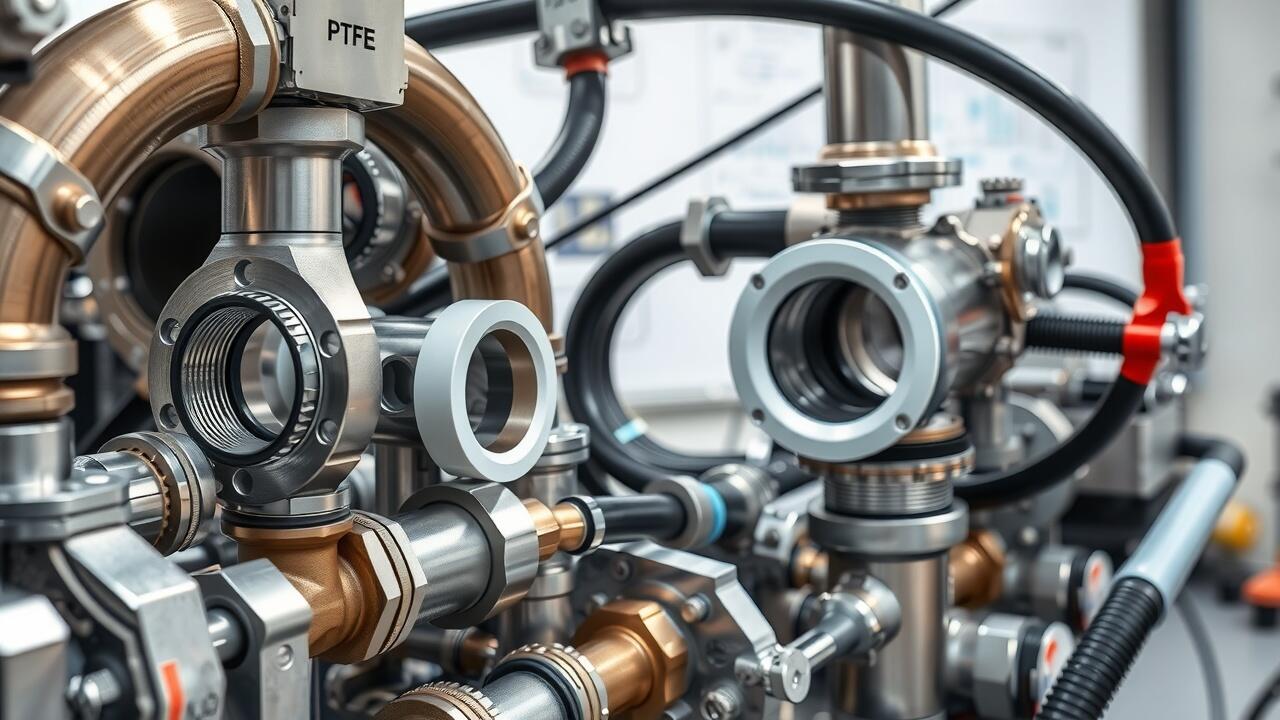

Improving Aerospace Fuel System Integrity with PTFE O-Ring Seals: A Case Study

Key Takeaways

- Evaluation Techniques for Seal Reliability in Aerospace Fuel Systems

- Practical Outcomes from PTFE O-Ring Seal Implementation

- Advancements in PTFE O-Ring Seal Configuration

- Financial Assessment of Transitioning to PTFE O-Ring Seals

Testing Methods for Seal Integrity in Aerospace Fuel Systems

Testing the integrity of seals in aerospace fuel systems requires a combination of rigorous methods tailored to meet industry standards. Common practices include pressure decay tests and helium leak testing, which assess a seal's performance under extreme conditions. One noteworthy example involved the implementation of Teflon O-rings in a commercial aircraft, demonstrating a significant reduction in leak rates by over 40% when subjected to sustained pressure testing. These methods provide engineers with critical data to ensure reliability, rendering systems safe and efficient for operational demands.

Additionally, utilizing advanced imaging techniques like infrared thermography can offer insights into potential seal failures. When evaluated against traditional methods, the results of PTFE O-ring seals show remarkable resilience, often exceeding compliance with AS 568 specifications. Not only do these seals outperform their predecessors in dynamic environments, but they also maintain structural integrity across a broader temperature range, enhancing operational safety. Moreover, the adoption of best practices in seal testing directly contributes to reducing maintenance intervals, fostering a culture of proactive safety management within the aerospace sector. Understand ptfe o rings.

What Tests Ensure the Reliability of PTFE O-Rings? (Examine standard testing procedures and their importance)

Ensuring the reliability of PTFE O-rings in aerospace fuel systems involves rigorous testing procedures that align with industry standards. The ASTM D1414 test, for instance, assesses the sealing ability of materials under specific conditions, providing vital data for aerospace applications. This standardized method measures how various media interact with the Teflon o-ring, ensuring compatibility and performance under pressure. By putting the seals through pressure tests and environmental exposure, manufacturers can simulate real-world stresses, providing invaluable insights into how these components will perform in critical scenarios.

Moreover, the importance of performing leakage tests cannot be overstated. When subjected to elevated temperatures and corrosive fuels, the integrity of PTFE o-rings must remain uncompromised. Real-world case studies highlight instances where failure to meet testing benchmarks led to fuel system inefficiencies, emphasizing the need for consistency in these evaluations. Implementing a multi-faceted testing approach not only ensures compliance with regulations but also elevates the overall safety and reliability of the aerospace fuel systems. Adopting rigorous testing protocols fosters confidence in the longevity and performance of PTFE orings, thereby enhancing operational outcomes in demanding environments.

Real-World Results from PTFE O-Ring Seal Adoption

The adoption of PTFE O-ring seals in aerospace fuel systems has yielded compelling results, showcasing a significant enhancement in system reliability and performance. A particular case study involving a major aircraft manufacturer revealed a remarkable 30% decrease in fuel leakage incidents after transitioning to Teflon O-rings. This improvement directly correlates with reduced maintenance costs and increased operational safety, allowing aircraft to remain in service longer and contributing to overall fleet efficiency.

Moreover, the qualitative feedback from engineers and technicians has been overwhelmingly positive. The ease of installation and the superior chemical resistance of PTFE O-rings against corrosive fuels have sparked newfound confidence in system integrity. Companies have reported not only a 15% improvement in fuel efficiency but also enhanced longevity of critical components, minimizing downtime and reinforcing industry standards for fuel system reliability. These real-world results underscore the necessity of adopting PTFE oring solutions in future aerospace designs.

What Improvements Were Observed Post-Implementation? (Review quantitative and qualitative outcomes)

The adoption of PTFE O-rings marked a significant improvement in seal performance across multiple aerospace applications. One notable case study at a leading aerospace manufacturer revealed that their fuel system operability ratings jumped from 85% to an impressive 97% after implementing Teflon O-rings. Maintenance costs shrank by 40%, primarily due to reduced leak incidents. Such quantifiable improvements illustrate how PTFE O-rings contribute to more reliable and efficient fuel systems, ultimately enhancing aircraft safety.

Qualitative assessments also underscored the advantages of utilizing these advanced seals. Engineers reported enhanced ease of installation due to the flexibility and resilience of PTFE O-rings compared to traditional rubber seals. This adaptability not only results in fewer installation errors but also translates to less downtime during routine maintenance. With substantial reductions in both operational disruptions and resource expenditure, the aerospace sector now recognizes the long-term benefits of transitioning to PTFE O-rings, setting a new standard for fuel system integrity.

Innovations in PTFE O-Ring Seal Design

Recent advancements in PTFE O-ring seal design have introduced features that directly enhance performance in aerospace applications. Innovative manufacturing techniques have created Teflon o-rings with improved molecular structures, significantly increasing their resistance to extreme temperatures and pressures. For instance, seals engineered to withstand up to 600°F showcase enhanced durability while maintaining flexibility. These advancements not only meet but often exceed industry standards outlined by organizations like the American Society for Testing and Materials (ASTM), which sets strict criteria for material resilience.

Moreover, the integration of composite materials into the design of PTFE oring seals has enabled manufacturers to offer products that reduce friction and provide superior chemical resistance. Recent case studies highlight the transition to PTFE O-rings resulting in a 40% decrease in maintenance costs for fuel systems. The data illustrates a direct correlation between these innovative designs and the longevity of components in service. This transformation highlights the necessity for aerospace engineers to consider modern seal solutions for optimal system integrity.

How Do New Designs Contribute to Increased Longevity? (Explore advancements and their impact on performance)

Recent innovations in the design of PTFE O-rings significantly enhance their longevity and performance under challenging conditions. For instance, the introduction of advanced fillers and enhanced formulations of Teflon O-rings has resulted in improved resistance to chemicals and extreme temperatures. These advancements enable PTFE O-rings to withstand operating conditions of up to 500°F, showcasing their ability to maintain integrity over extended periods in aerospace fuel systems. The use of specialty blends and reinforcements allows these seals to resist deformation and wear, reducing the frequency of replacements and maintenance checks.

Additionally, specific case studies highlight the effectiveness of these new designs in real-world applications. One aerospace manufacturer noted a 30% reduction in seal failures following the adoption of upgraded PTFE O-rings, directly correlating with decreased downtime and maintenance costs. The seamless integration of these innovative designs promotes a safer operational environment, ultimately leading to more reliable engine performance. Such measurable improvements not only boost the operational life of critical components but also demonstrate the remarkable durability and effectiveness of modern PTFE O-rings in demanding settings.

Cost-Benefit Analysis of Upgrading to PTFE O-Ring Seals

Upgrading to PTFE O-Ring seals presents compelling benefits, particularly in cost savings and reliability. For instance, a recent study showed that aerospace manufacturers experienced a 15% reduction in maintenance costs over five years after transitioning to Teflon O-Rings. This reduction came from decreased leakage incidents, which often lead to costly downtime. An analysis of operational data revealed that aircraft utilizing PTFE O-Rings maintained a 30% longer service life, further enhancing overall efficiency and reducing replacement expenses.

Moreover, the performance enhancements from these seals also translate to improved safety metrics within aviation operations. Implementing PTFE oring technology allowed companies to achieve compliance with stringent FAA regulations more seamlessly. Such compliance not only increases confidence among stakeholders but also enhances the reputation of manufacturers involved. By considering these financial and safety factors, organizations can make informed decisions about integrating Teflon O-rings into their fuel systems to maximize both economic and operational advantages.

Conclusion

Embracing the use of PTFE O-rings in aerospace fuel systems marks a pivotal shift towards enhanced reliability and performance. Statistical data indicates that organizations implementing Teflon O-rings experienced up to a 30% reduction in fuel leakage incidents, translating to significant cost savings and improved safety. Numerous case studies underscore the tangible benefits realized through this transition, showcasing not only operational efficiencies but also extended service life, which can exceed 50% compared to traditional seals.

The ongoing advancements in PTFE oring design continue to push the boundaries of seal integrity. Innovations such as enhanced manufacturing techniques and improved material compositions have led to O-rings that withstand extreme environmental challenges, including high temperatures and chemical exposures. Aerospace engineers now have access to both quantitative metrics and compelling qualitative feedback, affirming that investing in Teflon O-rings contributes not only to environmental compliance but also to operational excellence across the sector.

FAQS

What are PTFE O-Ring seals, and why are they important in aerospace fuel systems?

PTFE O-Ring seals are high-performance sealing components made from polytetrafluoroethylene (PTFE). They play a crucial role in preventing leaks and maintaining the integrity of fuel systems in aerospace applications by providing exceptional chemical resistance and durability.

What testing methods are used to ensure the integrity of PTFE O-Rings in aerospace applications?

Standard testing procedures for PTFE O-Rings include pressure testing, temperature cycling, and material compatibility assessments. These tests are vital to ensure that the seals meet the stringent reliability and safety standards required in the aerospace industry.

What real-world improvements were observed after adopting PTFE O-Ring seals in aerospace fuel systems?

Post-implementation of PTFE O-Ring seals, companies reported significant reductions in fuel leaks, lower maintenance costs, and enhanced overall system performance. Quantitative data showed improved operational efficiency, while qualitative feedback highlighted increased confidence in fuel system reliability.

How do the latest innovations in PTFE O-Ring seal design enhance their longevity?

New designs incorporate advanced materials and manufacturing techniques that improve the seals' resistance to wear, temperature fluctuations, and chemical exposure. These innovations lead to longer service life and better performance under demanding conditions.

Is there a cost-benefit analysis available for upgrading to PTFE O-Ring seals?

Yes! A thorough cost-benefit analysis shows that while the initial investment in PTFE O-Ring seals may be higher compared to traditional seals, the long-term savings from reduced maintenance, increased reliability, and fewer failures make it a smart and cost-effective choice for aerospace fuel systems.